Create a Product Spec in Four Steps

Within every new product initiative, we must create a product spec. As a result, engineers need to know what to “build to.” Meanwhile, modern innovation methods begin with customer needs as the input to the process, leaving an important, and too-often unanswered question, “How do we get from a customer need to a product specification?” It’s time to clarify this connection.

First, technically speaking, we’re actually not creating a spec. Instead, we are creating a target value that we hope to achieve. The specification is what we end up with – after our best attempt to hit the target. However, that’s largely an issue of semantics. Practically speaking, engineers will use these terms interchangeably as they create specification documents.

What about “customer requirements?”

The one word that can be problematic is the word “requirement” or “customer requirement.” The meaning is vague. Is it a a customer need? Or, is it a product specification? This ambiguity creates havoc, slowing progress. If your company insists on using this term, just make sure that it’s well-defined. The word “requirement” can either be a customer need or a product specification. The only thing it cannot be, is both. While this should be a central tenet of your innovation or product manager training, it’s often not understood.

As an illustration for the process of creating a product spec, we’ll use a scenario. Imagine that you are a textile engineer. Your company makes waterproof fabrics for rain gear. Your customers produce rain jackets and pants. With that in mind, let’s introduce the four steps to create a product spec:

- Begin with the best possible outcome statement.

- Conduct a Preference Interview

- Determine your strategy for each outcome

- Set your product spec (based upon the strategy)

Warning: Details ahead!

Before we begin, be advised that we have to be detail-oriented. For a fruitful discussion of the process to create a product spec, theory alone will not be enough. This exercise lives within the confluence of strategy and data analysis. Therefore, we have to get our data-analyzing hands dirty. There will be math! This dialogue contains more minutia than most business leaders want to entertain, but it’s required to address the topic.

The Four Steps to Create a Product Spec

1. Begin with the best possible outcome statement.

To create a product spec that will deliver value, the inputs must be right. After all, any process needs good inputs to have good outputs. A critical innovation skill is the ability to write outcome statements. For our rain gear fabric, imagine that our customers are asking for “better waterproofness” during Discovery Interviews.

For our outcome statement, it might be tempting to go with “Maximize waterproofness” as the outcome. An inexperienced team might feel good about this statement and continue.

However, this is not a great outcome, because:

- As a textile engineer, you know that “waterproofness” doesn’t stay the same over a product’s life. It begins at one level and degrades. And it’s not clear when the measurement is to be taken. As a virgin fabric? After manufacture? After some use?

- It’s ambiguous about the error itself. That is, what is it? What’s going wrong? What’s to be corrected? What is the problem?

The best outcome statements are not subject to interpretation. Also, we need key relevant contextual details. These should be unearthed when probing. For this outcome, imagine that our customers, who make rain gear, have provided this juicy bit: “The biggest issue with waterproofness is the degree to which it is damaged by repetitive washing machine cycles. It should remain waterproof after 200 washes.”

After probing, we end up with this:

Minimize the loss of waterproofness due to repeated washing machine cycles

As a result, we now have a direction, a metric, and a context – the number of washing cycles. It’s better because we are minimizing the “bad thing”, the loss of waterproofness. This is a great start on our path to create a product spec.

Further reading and references:

- E-learning module #16: Capturing Customer Outcomes – This module covers how to probe, capture, and craft outcome statements as part of New Product Blueprinting Step 2, Discovery Interviews. (Available as a subscription to Blueprinter software subscribers.)

- What Customers Want , Anthony Ulwick (2005)

- The Statue in the Stone: Decoding Customer Motivation with the 48 Laws of Jobs-to-be-Done Philosophy, W. Scott Burleson (2020)

2. Conduct a Preference Interview

(Other methods may have different means of data gathering and analysis. Here, we describe how it is done within New Product Blueprinting.)

Within New Product Blueprinting’s Step 3, Preference Interviews, we will obtain that data that we need to:

- Prioritize the outcomes (using the MSG)

- Determine how to measure this outcome

- Determine the relationship between Performance and Satisfaction

To prioritize , customers will score each outcome for Importance and Satisfaction.

In Blueprinting, these questions will be:

How Important is it to “Minimize the loss of waterproofness due washing machine cycles?”

How Satisfied are you with your ability to “Minimize the loss of waterproofness due to repeated washing machine cycles?”

In New Product Blueprinting, Importance is rated from 1-10. The scale that goes from “Not important at all” to “Critical.” Satisfaction is likewise rated from 1-10. The scale goes from “Totally Unsatisfied” to “Totally Satisfied.” A key point on the Satisfaction scale is 5, calibrated to “Barely Acceptable.”

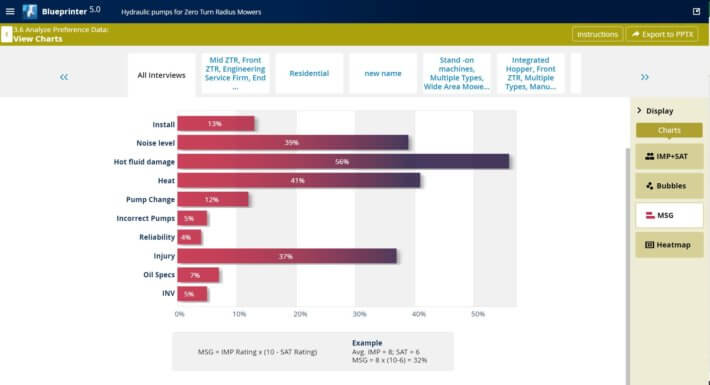

From these scores, how do we learn the intensity of desired improvement? With the MSG, or “Market Satisfaction Gap.” It’s the gap between Importance and Satisfaction. The formula is: MSG = IMP x (10-SAT). So, in our example, let’s presume the mean IMP = 8 and the mean SAT = 6. In which case, MSG = 8 x (10-6), or 32. In New Product Blueprinting, we interpret MSG’s greater than 30 as a problem worth solving. As a result, we have a 32. Therefore, we have evidence that customers will reward us for improvement.

Measuring the outcome

Next, during the Preference Interview, we learn how to measure the outcome. In our project, we find that waterproofness is measured in units of “hydraulic pressure of water, with units of mm-H2O”. This is the pressure to move a column of water 1 mm high. It turns out that waterproofness isn’t binary. It’s not like a fabric either is or is not waterproof. Instead, there’s a continuum. With enough pressure, water can penetrate any surface. Further, we learn that over a garment’s lifetime, it’s presumed there will be 200 washes. We also find that the initial waterproofness of the virgin fabric is 20,000 mm-H2O.

As a testing protocol, clothing manufacturers have a trial where they force water through the fabric. They measure the pressure at the failure point. There are multiple home-grown devices, but they all generally use this principle.

Mapping Performance vs. Satisfaction

Finally, in the Preference Interview, we get a couple of key bits to map Performance vs. Satisfaction. We do this primarily with two data points: 1) the Performance level for which Satisfaction is “Barely Acceptable” (rated as a 5) and “Totally Satisfied” (rated as a 10).

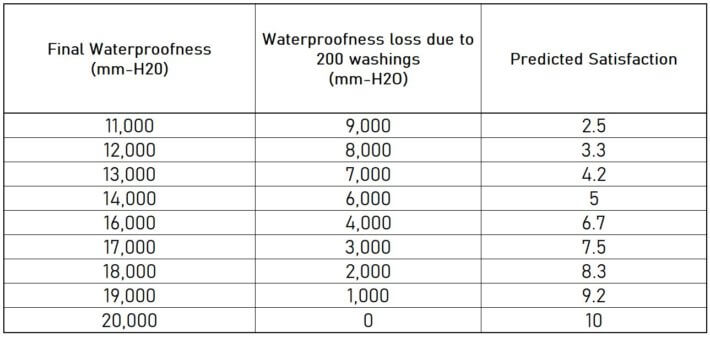

In our project, a final rating of 20,000 mm-H2O (with zero degradation) equates to “Totally Satisfied,” and a rating of 14,000 mm is “Barely Acceptable.” From here, we assume a linear relationship, resulting in the following equation:

Predicted Satisfaction = 10 – 0.00083 x (Loss in Waterproofness in mm-H2O)

(This equation comes with a lot of caveats, beginning with the assumption of linearity. You can create this equation with some knowledge of regression analysis using a statistical package or spreadsheet. But Blueprinter® software subscribers have it easy! The software builds the formulas for you. Plus, in Blueprinter, you can model non-linear relationships as well.)

From here, we will uncover the performance levels that customers are getting today. And with that, we can create our strategy for each outcome. It should not be surprising that we need quantitative analysis to create a product spec. Consequently, we embrace objective measures throughout the process.

As a result, we have the following table of Predicted Satisfaction:

We have the data! Let’s build a strategy.

Further Reading:

3. Determine your strategy for each outcome

Will it now be obvious how to create a product spec? No. Sorry. Blueprinting doesn’t answer this question for you. (If a process promises this, run the other way.) However, it gives the tools and insight to create a plan. A plan driven by your strategy. For example: Do you want higher market share? Higher margins? Both? Are you the industry leader? Is your segment mature? Are you seeking to penetrate a new segment? Expanding into adjacent spaces? These questions are beyond this article’s scope. However, we can over-simplify the actions we’re likely to pursue into three categories: 1) Investigate a cost decrease, 2) Match the competition, or 3) Exceed the competition.

When would you investigate a cost decrease?

Pursue with low Importance scores or when Satisfaction > Importance. If not important enough, there’s no reason to improve anything.

As part of your investigation, check the cost drivers that prop up performance. You might be able to reduce performance and find a cost decrease in the bargain. CAUTION: This tactic has risks. The only true way to know when you fall off the cliff is when you begin to fall. Therefore, you might seek additional validation.

When would you match the competition?

This might be surprising, but you’ll do this most of the time. As discussed before, we sometimes reduce performance when we can also lower cost. As just discussed, this can be risky. As we’ll discuss next, we may improve performance. But since this likely adds cost, it also can be risky. Customers might not be willing to pay the premium.

Therefore, for a new product, we don’t want to take big risks on every outcome. If we do so, we’re likely to go too far. Solving some problems while accidentally, creating others.

When would you exceed the competition?

You’ll do this when you have high MSG scores (High Importance and low Satisfaction). Your product’s superiority against these outcomes will become the identity, the positioning, the branding, and ultimately – the sales pitch for your product. For these, you want to crush the competition. You want to leave zero doubt as to your product’s dominance. In practice, there are likely only a few of these, perhaps as few as one!

4. Set your product spec (based upon the strategy)

All that’s left then, is to pursue the strategy. For this, let’s go back to the numbers.

Strategy 1: Investigate a Cost Decrease

When we think about the process to create a product spec, cost decreases may not be the first thing we think about. It might not seem as “fun.” But on the whole, companies often ignore the over-performing areas, leaving vulnerabilities to competitors’ low end attacks.

For the outcome statement “Minimize the loss of waterproofness due to washing machine cycles”, let’s imagine that IMP = 4 and SAT = 9, yielding an MSG = 4, which is quite low. Significantly below the threshold of 30.

Let’s imagine that in this scenario, that the average decrease in waterproofness after 200 washes is 1,200 mm-H2O. This equates to a decline from our virgin fabric of just 6%. Too small to be noticed by customers. The 6% loss is acceptable, with a predicted Satisfaction rating of 9, just barely below “Totally Satisfied.”

Does that mean that there’s nothing to do from an innovation perspective?

Not at all, but instead of increasing performance – we investigate cost reduction. Keep in mind, that we’re not seeking to necessarily decrease performance. That wouldn’t make sense. But we would be willing to sacrifice a bit if we can find a cost reduction along the way.

For example, we could create a target value equal to an 1,850 mm-H2O loss after 200 washes. Will customers still accept it? Our Blueprinting data provides the compass. According to our analysis above, we predict that customer satisfaction would drop from 9 to 8.5. As a result, the MSG would increase to 6, still way below 30. Our data suggests that this would still be acceptable.

And now, we have an innovation challenge! We turn our R&D and procurement folks loose to find a new fabric, with a lower cost, that meets or exceeds that spec. We ultimately find one that costs 25% less per square yard.

By reducing our cost, we’ve created value. We have options to collect this value for our company. We could drop our price (to increase market share) or maintain our price (to increase our margins).

Proceed with caution

As a reminder, it’s always risky to decrease performance as compared to the competition. Be careful. But with good data analysis, you have the insight to move forward safely. Essentially, you’re correcting a spec that was previously over-designed. This is an underutilized tactic. Embrace it and you’ll find plenty of opportunities.

Strategy 2: Match the Competition

“Matching the Competition” is the lowest risk path to create a product spec. On one hand, we’re hesitant. We don’t want to build a “Me Too” product. But we should recognize that for most of our specs, this is exactly what we will do – stay close to the competition.

Imagine that we have IMP = 9 and SAT = 8.5, yielding an MSG = 13.5. This is a “Table Stakes” outcome. There’s no opportunity to raise performance. However, with high importance, it would also be risky to reduce performance.

To create this spec, we note that the competition has a loss of 1,800 mm-H2O with 200 washing cycles. This corresponds to an 8.5 satisfaction score. To create our own target, we likewise adopt 1,800 mm-H2O. We choose the low-risk path for this outcome; just setting our spec with the rest of the crowd.

Strategy 3: Exceed the Competition

Of course, when we think about the process to create a product spec, this is what we dream about! Going up-market. Increasing performance. And with a high MSG, that will be the strategy. Imagine that for “Minimize the loss of waterproofness due to washing machine cycles” that we have IMP = 9.5 and SAT = 3.0, yielding an MSG = 66.5, certainly well beyond the threshold of 30.

From our Preference Interviews, we see that our leading competitors (as well as our own fabrics) experience a loss of 8,400 mm-H2O after 200 washes. As a result, we have a final rating of 11,600 mm-H2O. For end consumers, that means that in a heavy rain, they’ll get wet.

Create a product spec

Therefore, we’ll set a higher target value. Suppose we take aim at a new Satisfaction of 8. A big improvement over the current SAT =3. Looking at our regression equation, this presents a loss of 2,400 mm-H2O. Resulting in a final waterproofness of 17,600 mm-H2O. At this level, the garment will still be exceptionally waterproof, even in the hardest of rains.

Moreover, we have our spec, but we have more than that. We have the heart of a new value proposition.

Further Reading:

- New Product Blueprinting, Dan Adams (2008)

- Blue Ocean Strategy, W. Chan Kim and Renee Mauborgne (2004)

- The Statue in the Stone: Decoding Customer Motivation with the 48 Laws of Jobs-to-be-Done Philosophy, W. Scott Burleson (2020)

When Creating a Product Spec: Something to Consider

A final question for the product managers, developers, and leaders: Does this seem complex? As a data-driven process, it can appear that way. However, it’s greatly simplified with Blueprinter® software to do the calculations. With Blueprinter, there’s no need to make regression equations. Plus, you can do as many “What if” analyses as you want while comparing your strategy to what’s feasible.

Is this a black box to create a Product Spec?

Above all, it’s been the process engineer’s dream to have an innovation process that takes customer needs in one end and spits out specifications. Is that what Blueprinting does? No. In fact, this “black box of innovation” was the promise of a process called QFD. But it failed. All those black box processes fail.

Why do the “black box” processes fail?

Because creating specs is a strategic exercise. What is the strategy? Are you going up market or down market? Are you the market leader or a new entrant? What’s the corporate or division strategy? Are you diving deep into your core vertical market or looking to expand the territory? Spreadsheets and software cannot do this alone. However, with a combination of the right VoC tools, such as Blueprinter software, great strategy, and the minds to execute, you can create specifications that build value. Value that you can extract in many ways such as increased market share, higher margins, or even better, both!

Comments