If you sell into a concentrated B2B market (one with just a few customers), your voice-of-customer interviews should have two goals: “insight” plus “engagement.” The latter is important: You want these big customers to be impressed and eager to work with you, not your competitors.

These 10 approaches help you engage your customers when interviewing them to understand their needs: 1) Kill the questionnaire. 2) Let customers lead the interview. 3) Discuss their job-to-be-done. 4) Project your notes so they can see them. 5) Focus on customer outcomes. 6) Learn how to probe deeply. 7) Don’t sell or solve. 8) Get quantitative in your VOC. 9) Use triggers to generate fresh ideas. 10) Use B2B-optimized interview tools. (See the 2-minute video, Engage your B2B customers.)

These are explained in the article, The Missing Objective in Voice of Customer Interviews

If you haven’t explored Design Thinking for your product development yet, I highly recommend you do. It brings seven important benefits: 1) stronger value propositions, 2) rapid customer insight, 3) improved customer engagement, 4) potential for transformational innovation, 5) less squandered R&D, 6) reduced commercial risk, and 7) the erosion of functional silos.

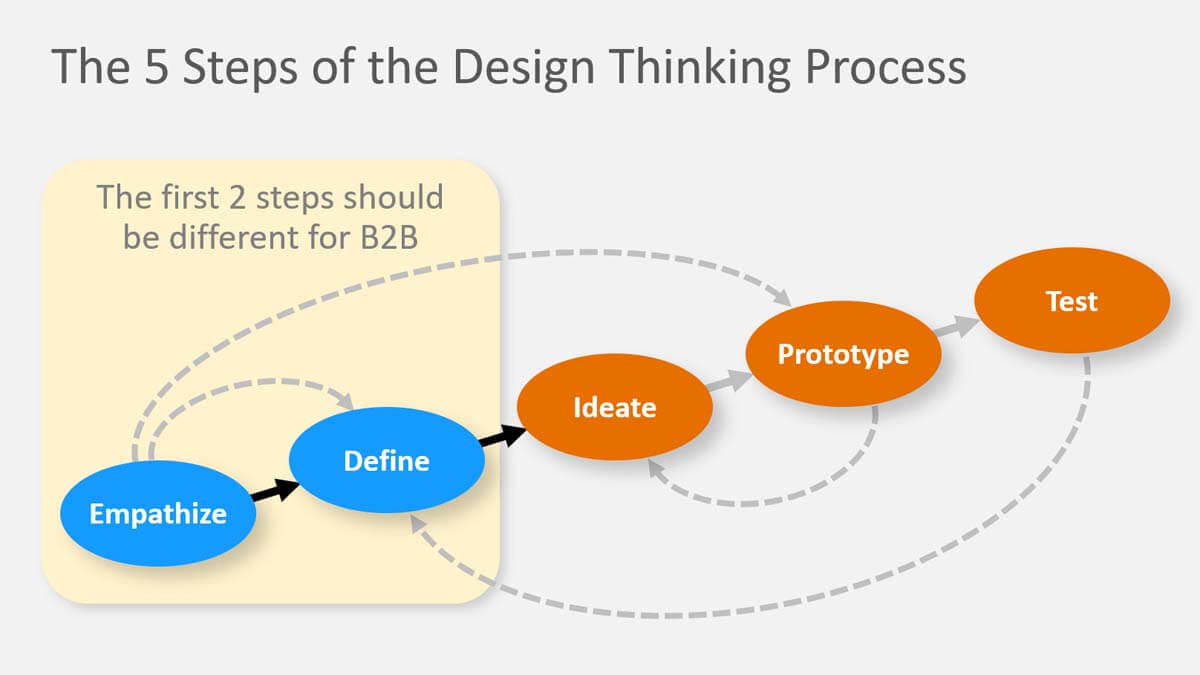

But if you’re a B2B company, don’t simply use Design Thinking as it’s taught in design schools. You can optimize it for B2B, especially the first two steps, “empathize” and “design”… using B2B-optimized Discovery and Preference interviews.

More in white paper, Design Thinking Optimized for B2B

Portfolio management links strategy with execution for new product development. A Voice of the Customer program maximizes ROI for all new product initiatives, whether incremental or breakthrough. ... Read More

We’ll examine 12 parts of a B2B business case format used by more than a thousand new-product teams. Our research will show you which sections are the most critical… including the part teams bungle most often. Do 12 parts seem like too many? We’ll close with a sensible business case “short-cut,” the 6-part market case. This ... Read More

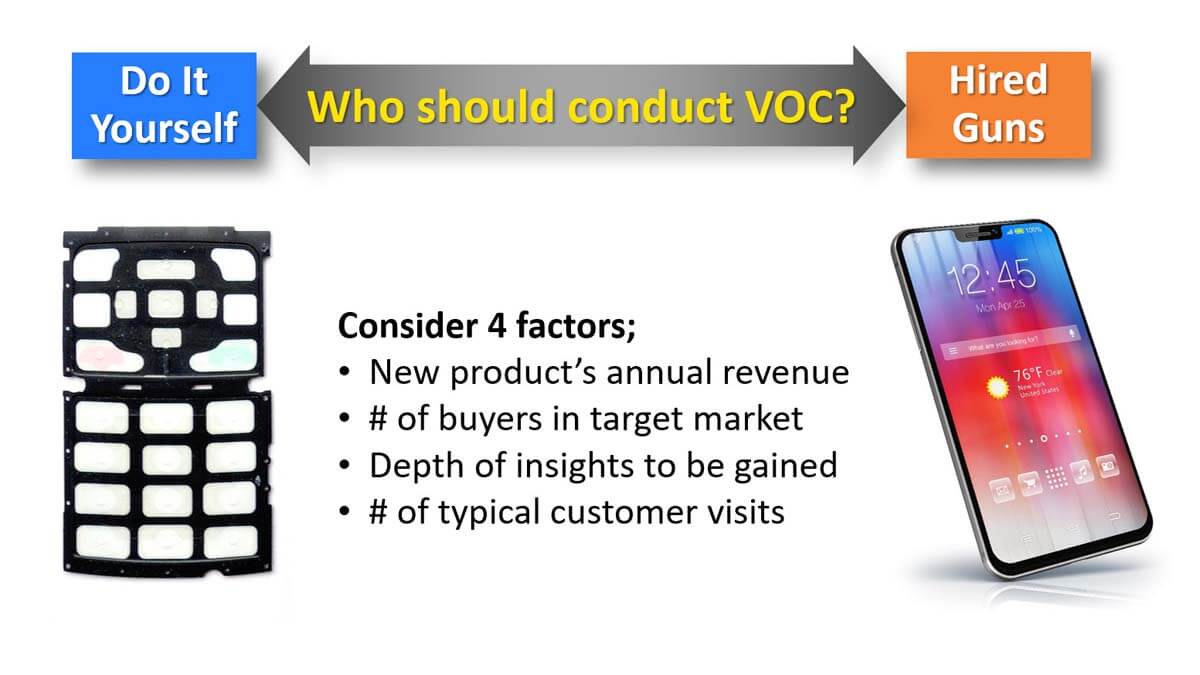

Are there times when you should use an outside firm—”a hired gun”—to conduct your interviews? Consider 4 factors: 1) Hired guns work well if you have a big budget and success is all about this very large product launch. 2) If you have millions of prospects, outside expertise can manage the sophisticated surveys and statistics needed. 3) If you don’t need to gain deep, first-hand insights, a marketing firm’s report is fine. 4) If you’re not already spending much direct face-time with customers, let a marketing firm conduct this market research.

In general, though, when you’re serious about bringing real innovation to a targeted market segment, your people should do the heavy lifting. Understanding market needs is a competitive advantage you shouldn’t try to outsource.

For more, see 2-minute video, When to use “hired guns” for VOC

Henry Ford is often cited for a reason to not interview customers: “If I’d asked my customers what they wanted, they would have told me a faster horse.” But this is flawed thinking for B2B markets. There are indeed B2C cases where customers can’t tell you much about their needs. Ask me what I want in a video game, men’s suit, or snack food, and I’ll probably need to see a prototype. Then I can play with it, try it on, or taste it (hopefully in that order).

Besides, B2C company employees are end-consumers themselves… so they’ve already got a good idea what consumers want. Bottom line: Your B2B customer can absolutely tell you the outcomes they want (desired end results). Once you know the “what,” it’s up to you to figure out the “how” (your new product solution).

For more, see 2-minute video, Avoid the faster horse fallacy

A missile strike? Well, that sounds a bit aggressive, doesn’t it? But consider the two targeting steps you’d take in the military, before firing those missiles: 1) survey all possible enemy positions, and then 2) isolate the high-value targets. You should do the same in the front-end of innovation, before the development stage: “Step 1” ... Read More

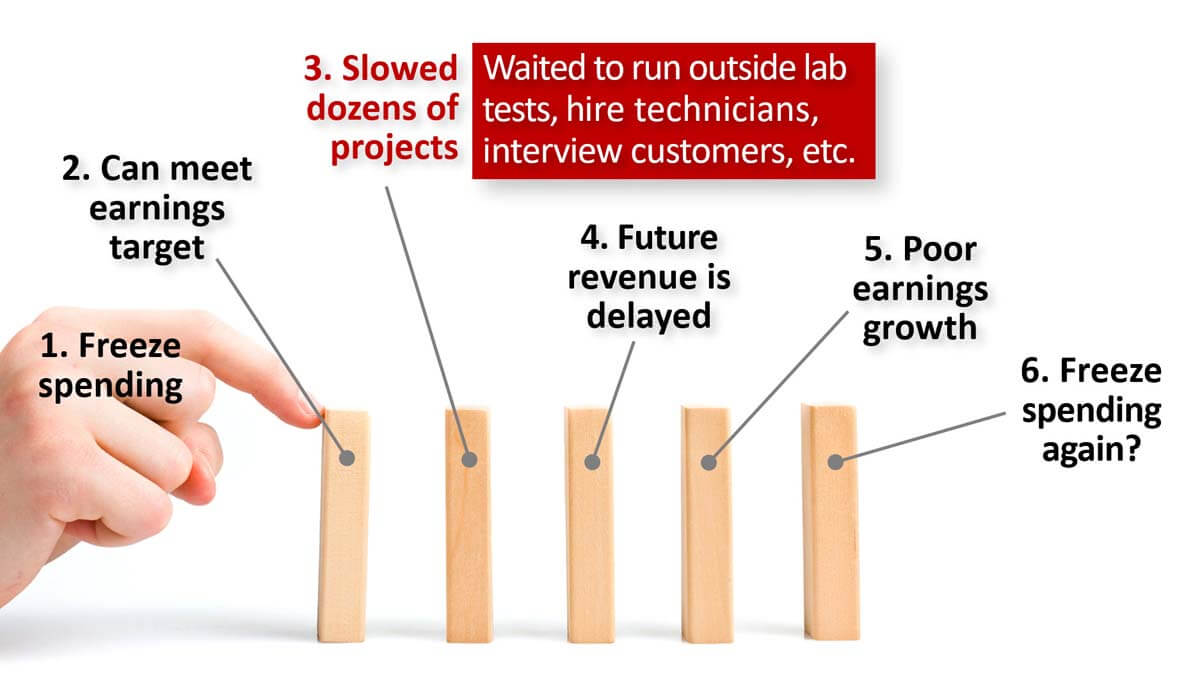

When you change a system, you always have a second-order effect. You can’t tip just one domino. Freeze discretionary spending this quarter and you’ll slow dozens of projects, as teams wait to run outside lab tests, hire technicians, interview customers, etc. Product launches are pushed back, delaying future growth. Otherwise-bright business leaders suffer from first-domino fixation over and over.

And most don’t learn from it. How often have you heard, “Well, our growth problem is all those crazy spending freezes the last few years”? Never? Yeah, that’s what I thought. I call this first-domino amnesia.

More in 2-minute video, Avoid the pitfalls of 2nd order effects

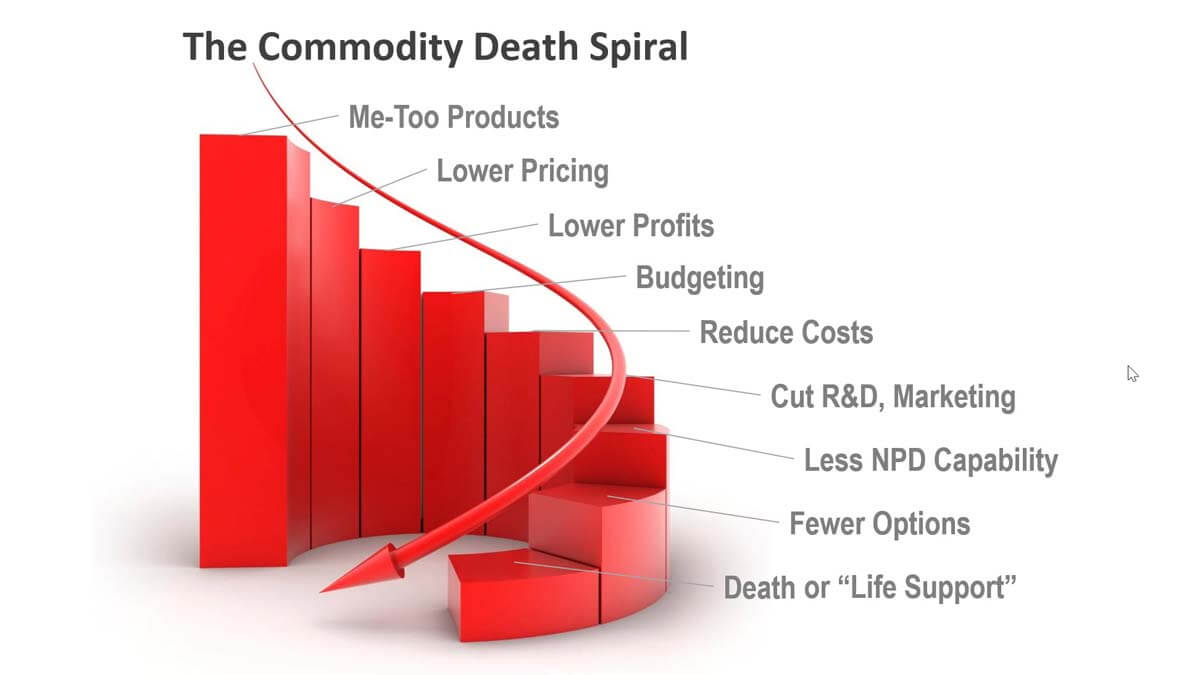

Here’s how the Commodity Death Spiral works: First, you stop innovating and offer me-too products that are interchangeable with competitors’. This lets purchasing agents demand lower pricing, which lowers your profits. Now it’s budgeting time and your boss wants higher—not lower—profits, so you must reduce costs. You cut R&D and marketing since you don’t need them this year. Of course, you’ll have even less new product development capability next year.

Eventually, you reach the point of no return, and your business dies… or goes on “life support” and is no longer relevant. Sadly, many businesses are on this downward spiral right now, and either don’t know it, or don’t want to admit it. They need a wake-up call, or the employees in that business will suffer.

More in this 2-minute video, Avoid the commodity death spiral

Design thinking is a powerful methodology for solving “wicked problems.” Unlike the well-stated problems we were given to solve in engineering school, these require figuring out what to work on, not just how to solve the problem. This perfectly describes real-world new product innovation, where we need to first understand customer needs.

As this diagram shows, the first two steps are “empathize” and “define.” Here’s the good news for B2B producers: You can do this much more effectively that B2C counterparts by using Discovery interviews (for “empathize”) and Preference interviews (for “define”). Check out this white paper to see why… and how: Design Thinking for B2B

In general, we do consider in-person interviews to be the gold standard. But there are 10 advantages of virtual VOC you shouldn’t overlook: 1) lower cost, 2) reaching dispersed customers, 3) viewable probing tips, 4) training for colleagues, 5) probing suggestions, 6) assistance for note-taker, 7) rapid de-briefing, 8) easier scheduling, 9) low-impact cancellations, and 10) greater project speed. To maximize effectiveness and efficiency, you’ll be wise to blend and balance both types of VOC. (See 2-minute video, Conduct virtual customer interviews.)

More in white paper, Virtual VOC

In 1965, DuPont scientist Stephanie Kwolek synthesized the first Kevlar polymer, an amazing fiber with five times the strength of steel. DuPont invested several hundred million dollars to commercialize the technology for tire cords, with disappointing results. It would be another decade before the company found its first major market for this material: bullet-proof vests.

How well does your company commercialize technology? Want to do it faster, more efficiently, and with greater confidence? You can, with six steps outlined in this white paper, Commercialize technology in 6 foolproof steps.

More in this 2-minute video, How to pursue transformational projects

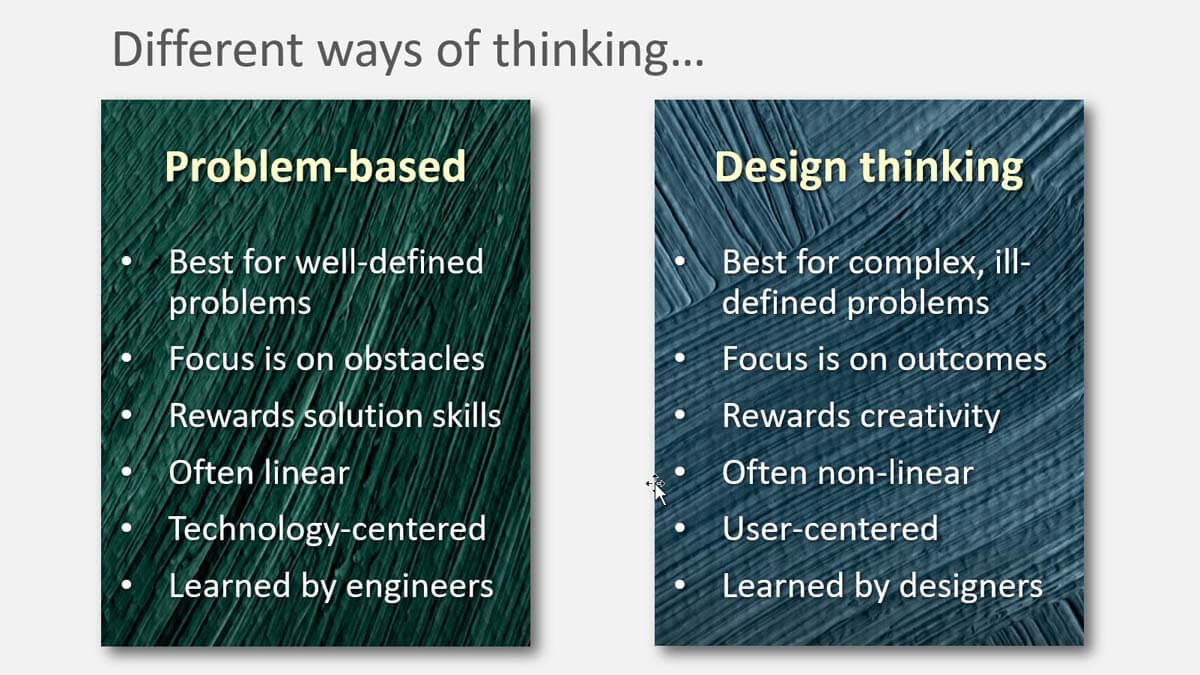

Design thinking isn’t new: The concept was first introduced by Nobel Prize laureate Herbert A. Simon in his 1969 book, The Sciences of the Artificial. It’s been “catching on” more and more in new product development circles, which is a very good thing. My favorite part is that it doesn’t start with well-defined problems, like the ones we were handed in engineering school. Rather, it’s a user-center process that encourages us to enter the customers’ world and understand it better. Especially their desired outcomes. This graphic shows the differences.

More in white paper, Design Thinking Optimized for B2B

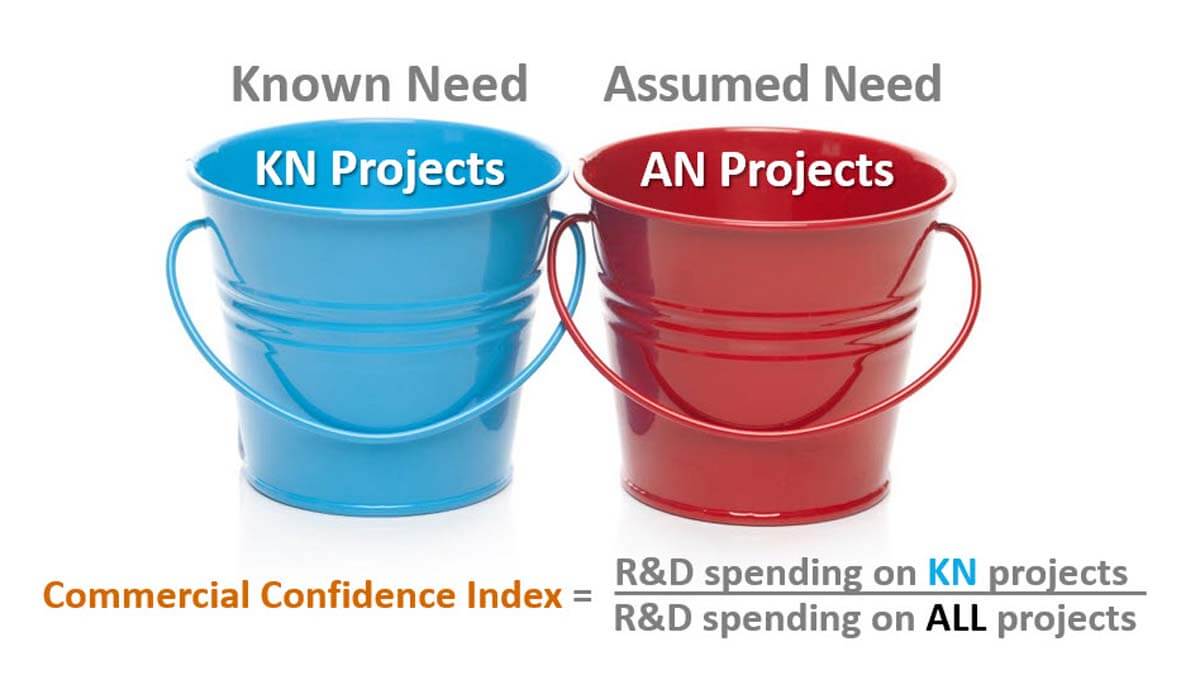

Yes, it’s called the Commercial Confidence Index (CCI), and it’s easy to calculate: Step 1: Record your annual R&D spending for each significant product development project. Step 2: For each project, ask if you have quantified evidence of customer needs, e.g. Market Satisfaction Gaps. If “yes,” the project goes in the “Known Need” bucket. All others go in the “Assumed Need” bucket. Step 3: The CCI is your annual R&D spending on Known-Need projects divided by annual spending on all product development projects.

More in 2-minute video, Employ new growth metrics